AI for Science: Shuimu Biosciences Partners with Volcengine to Reshape Life Sciences R&D with Data

Cryo-electron microscopy (cryo-EM) is providing crucial atomic-level structural data for the AI for Science era. Leveraging its atomic-resolution imaging capabilities, researchers can observe the true morphology of biological and material structures with unprecedented precision. Recently, following the partnership between Volcengine and Shuimu Biosciences, a live stream titled "Cryo-EM + AI Platform Drives the New EraFuture of AI for Science," hosted by Volcengine, featured scientists from Shuimu Biosciences detailing the principles and achievements of the integrated intelligent computing platform SMART. This platform deeply integrates AI with cryo-EM technologiesy. Utilizing Volcengine's elastic computing power and secure storage capabilities, SMART has achieved seamless cloud collaboration across the entire workflow from data acquisition to analysis, effectively enhancing research efficiency and data value, thereby building a solid gound-truth data foundation for AI-driven scientific research.

Cryo-EM, often regarded as the "ROCKET" of research instruments, acquires atomic-level, clear, near-native state 3D structural data by flash-freezing samples and using electron beams for imaging. After parsing by AI, this data can systematically reveal information ranging from molecular structures to complex biological functions, accelerating the process of scientific discovery and validation.

A single Cryo-EM experiment often involves processing millions of particle images. The processes of 3D reconstruction and atomic modeling place extremely high demands on computational power, posing significant challenges to traditional computing architectures in balancing efficiency with flexibility. To address this, Shuimu Biosciences developed the SMART platform, which achieved a comprehensive solution covering the entire workflow from data collection and 3D reconstruction to atomic modeling. By deeply collaborating with Volcengine, a standardized, intelligent "data factory" was built up with the connection of cloud platform. This AI-drived platform provides next-generation infrastructure support for innovation in areas such as drug discovery, new material development, and other fields reliant on atomic-level manufacturing.

SMART: An Integrated Platform Improves efficiency of Atom-level Research Workflow

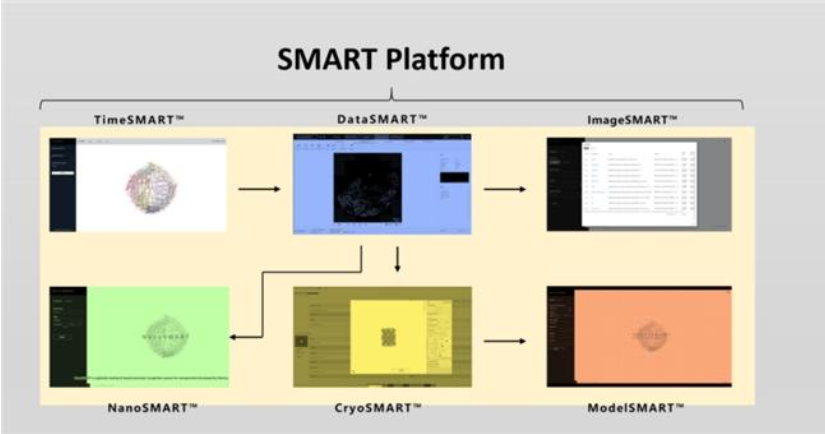

As the world's first AI-driven system independently developed by Shuimu Biosciences to achieve a full atomic-level workflow of data acquisition, 3D reconstruction and modeling. The SMART cloud platform deeply integrates AI, High-Performance Computing (HPC), and cloud computing technologies. It fundamentally addresses the industry sore points of traditional cryo-EM data analysis, including low efficiency, high barriers to entry, and reliance on foreign software. The overall architecture of the platform is shown below, which enabling seamless cloud-based progression from raw data to atomic structure.

Schematic Diagram of SMART Plaform for Cryo-EM

A complete workflow loop includes Five Intelligent Modules for atom-level study:

- TimeSMART: Enables intelligent scheduling and management of cryo-EM resources.

- ataSMART: Achieves autonomous control of the entire data collection process based on AI.

- ImageSMART: Monitors data quality and acquisition status in real-time.

- CryoSMART: Utilizes computer vision algorithms for efficient 3D reconstruction.

- ModelSMART: Enhances atomic modeling efficiency by tens of times through AI modeling.

The only thing need to do for the users is submitting the protein sequence to the platform. An end-to-end services will be provided then, covering protein expression, cryo-sample preparation, and final structure determination. The cloud-based setup also facilitates global database interoperability, helping clients overcome geographical limitations and utilize cloud computing resources for DIY structure determination. Currently, the platform serves over 1,400 laboratories worldwide, enhancing research efficiency while providing crucial support for safeguarding national biological data security and ensuring self-sufficient control over research software.

High-efficiency and High-resolution Revolution driven by SMART with Collaboration of Volcengine

Leveraging its globally scaled cryo-EM platform, Shuimu Biosciences integrates three core modules, including protein experiments, Cryo-EM analysis, and AI computing, to build an industry-leading, closed-loop workflow encompassing "computing - protein wet lab - cryo-EM." Building on this foundation, the launched ProteinSMART protein design platform utilizes high-quality structure-sequence paired data to achieve full-scenario coverage from complex design to functional protein directed generation. Experimentally validated designs have demonstrated high affinity at the 100 nmol level for difficult-to-resolve targets, significantly improving protein development efficiency.

In partnership with Volcengine and other collaborators, Shuimu Biosciences has established an AI × Cryo-EM data infrastructure. Supported by the powerful computing capabilities of Volcengine's third-generation GPU instances, the SMART platform has achieved leapfrog development. This architecture provides millisecond-responsive elastic scheduling capabilities, increasing image recognition speed by 3 times. It successfully supported the platform in completing urgent antigen-antibody analysis within 72 hours and handling ultra-large projects of up to 151 TB.

The cloud-native architecture allows researchers to access platform functions anytime, anywhere without building their own infrastructure, reducing the release cycle for new AI algorithms from days to minutes. Combined with fine-tun grained security controls and flexible billing models, the platform has increased computational efficiency by 40% while reducing cryo-EM data processing costs by over 50%. The analysis cycle for membrane proteins has been shortened from years to months or even weeks.

Illuminate the Future of AI for Science based on Data Infrastructure Foundation

On September 11, 2025, the 2025 Hong Kong International Biotech Forum & Exhibition was successfully held in Hong Kong. The satellite forum, Data as an Asset became a focal point. Experts from various industries discussed about high-quality life science data and highlighted that data structuring and AI compatibility are key to achieving a scientific closed loop.

Today, SMART has evolved into a globally leading commercial integrated cryo-EM computing platform. Internally, it handles all computing tasks for Shuimu Biosciences' eight 300kV high-end cryo-electron microscopes. Externally, it has served over 500 research institutions and enterprises worldwide, with overseas clients accounting for approximately 50%.

Looking ahead, Shuimu Biosciences will continue its partnership with Volcengine, strategically providing sustained momentum for AI-driven scientific discovery and deploying AI in the life sciences sector to bridge the loop from microscopic structure , macroscopic properties to engineering design. We believe that when the microscopic world is illuminated by computation, AI for Science will bring not just "faster tools," but "better science."