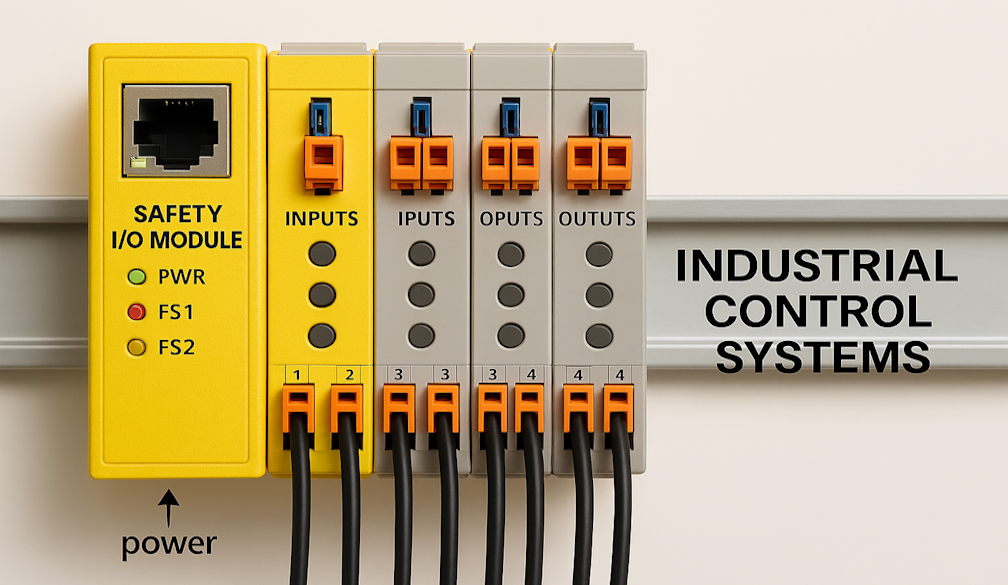

Safety Certified I/O Module for Reliable Industrial Control Systems

Industrial automation relies heavily on accuracy, speed, and safety. In environments where machinery, people, and processes operate side by side, safety cannot be treated as an afterthought. A safety certified I/O module is designed to meet strict safety standards while managing critical input and output signals within automated systems. These modules form a vital link between sensors, actuators, and control units, ensuring that safety-related signals are processed reliably and without compromise.

As industrial systems become more complex, the demand for certified safety components continues to rise. Safety certified I/O modules help organisations comply with regulatory requirements while maintaining smooth and efficient operations. They are especially important in applications where system failure could result in injury, equipment damage, or costly downtime.

Why Safety Certification Matters in Automation

Safety certification is not just a label; it represents rigorous testing and compliance with recognised international standards. Safety certified I/O modules are designed to perform reliably even in fault conditions, reducing the risk of unsafe system behaviour. In critical applications, this reliability is essential for protecting both personnel and assets.

Certified modules are evaluated for their ability to detect faults, manage signal integrity, and respond appropriately to abnormal conditions. This level of assurance allows engineers to design systems with confidence, knowing that safety functions will operate as intended when they are needed most.

Role of Safety Certified I/O Modules in Control Systems

A safety certified I/O module manages signals that are directly related to safety functions. These may include emergency stop buttons, safety light curtains, pressure switches, and position sensors. The module ensures that these signals are transmitted accurately to the control system and that appropriate actions are taken immediately when unsafe conditions are detected.

By handling safety-related inputs and outputs separately or in conjunction with standard control signals, these modules help create a structured and reliable safety architecture. This separation reduces the risk of interference or miscommunication between safety and non-safety functions.

Design Features Supporting Safe Operation

Safety certified I/O modules are built with redundancy and fault detection in mind. Internal diagnostics continuously monitor signal paths and module health, allowing the system to identify issues before they escalate into failures. If a fault is detected, the module can trigger a safe state, such as shutting down machinery or isolating power.

Robust construction is another key feature. These modules are designed to operate in industrial environments where vibration, electrical noise, and temperature variations are common. High-quality components and protective housings ensure consistent performance over long operational lifespans.

Integration With Safety and Control Architectures

One of the strengths of safety certified I/O modules is their ability to integrate seamlessly with broader automation and safety systems. They can communicate with safety PLCs, distributed control systems, and monitoring platforms, allowing safety functions to be managed alongside standard process control.

This integration supports a unified approach to system design, where safety is embedded into the overall architecture rather than added as an external layer. Operators benefit from clearer visibility of system status, while maintenance teams gain access to diagnostic information that supports faster troubleshooting.

Applications Across High-Risk Industrial Environments

Safety certified I/O modules are used across industries where risk management is critical. Manufacturing facilities rely on them to protect workers around automated machinery and robotic systems. In process industries such as chemical processing, energy production, and water treatment, they support safety interlocks and shutdown systems that prevent hazardous conditions.

Mobile machinery and infrastructure applications also depend on safety certified I/O modules. In these settings, equipment often operates in dynamic environments where conditions can change rapidly. Reliable safety signal management helps ensure that systems respond correctly to unexpected events.

Supporting Compliance and Regulatory Requirements

Compliance with safety regulations is a major concern for industrial operators. Safety certified I/O modules are designed to meet recognised standards, helping organisations demonstrate compliance during audits and inspections. Using certified components simplifies the certification process for entire systems and reduces the risk of costly redesigns.

By incorporating safety certified modules into automation projects from the outset, engineers can build systems that align with regulatory expectations while maintaining flexibility for future expansion or modification.

Maintenance and Diagnostic Advantages

Modern safety certified I/O modules often include advanced diagnostic capabilities. These features provide real-time information about signal status, fault conditions, and module performance. Maintenance teams can use this data to identify issues early and plan interventions before failures occur.

Predictive maintenance supported by diagnostics reduces unplanned downtime and extends the lifespan of equipment. This proactive approach not only improves safety but also enhances overall operational efficiency.

Balancing Safety and Productivity

A common misconception is that increased safety measures slow down operations. In reality, well-designed safety certified I/O modules support productivity by reducing disruptions caused by accidents or equipment failure. Reliable safety systems allow processes to run smoothly, knowing that protective measures are always active in the background.

By minimising false trips and ensuring precise signal handling, these modules help maintain optimal system performance while upholding safety standards. This balance is essential in competitive industrial environments where efficiency and safety must coexist.

Long-Term Value of Safety Certified I/O Modules

Safety certified I/O modules represent a strategic investment in both safety and reliability. Their ability to manage critical signals, support compliance, and integrate with modern automation systems makes them indispensable in high-risk applications. Over time, the benefits of reduced downtime, improved safety, and simplified maintenance far outweigh the initial cost.

As industrial automation continues to evolve, the role of safety certified components will become even more significant. Safety certified I/O modules provide a strong foundation for building control systems that are not only efficient but also resilient and secure, supporting long-term operational success.